Acrylic engraving has been a popular form of decorating recognition awards since the early 90’s when laser engraving technology became accessible to the local trophy shop.

In this article, we are going to discuss the chemical composition of cast acrylic or Lucite®, the difference between cast and extruded acrylic materials, and some of the common decoration methods that are used in the trophy and recognition industry.

One thing to note about cast acrylic is that it is by nature optically clear, lighter, and has a higher resistance to chipping and breaking than glass which makes it an ideal substrate for trophies and awards.

Let’s begin by taking a closer look at two types of acrylic materials – cast acrylic and extruded acrylic.

Extruded Acrylic

Extruded Acrylic

Though extruded acrylic is less expensive than cast, it is not typically used in the awards industry for fabricating corporate acrylic trophies. Oftentimes you will find extruded acrylic used for certificate or photo covers that have been mounted on a plaque board or inside a wood frame.

Extruded acrylic is produced using a continuous manufacturing process that heats plastic PMMA (polymethyl methacrylate) pellets within a heated screw drive barrel to a molten temperature. The molten acrylic material is then forced through a shaping die which extrudes different shapes and sheet stock configurations.

You may find extruded acrylic in some of these shapes or substrates:

- Acrylic Tubing

- Acrylic Sheets

- Acrylic Films

- Structural Parts

- Signage

- Models

Extruded acrylic is often used in the manufacture of industrial parts since its properties allow for fabrication using traditional power equipment, CNC machining, and laser cutting.

It is not a suitable substrate for laser engraving because lasers do not produce the beautiful frosty white letters that is expected of acrylic engraving. When laser engraved, extruded acrylic produces a melted gray color which often crazes or in other words forms very fine internal cracks.

Cast Acrylic

Cast Acrylic

Often referred to as the acrylic of choice for engraving and acrylic award manufacturing. Cast acrylic has multiple benefits and the most important is its ability to be laser engraved. Unlike extruded acrylics, cast acrylic laser engraves with a beautiful white finish and can be surface engraved or engraved deeply in order to color fill the engraved area and add accent colors.

As with extruded acrylic, cast has exceptional optical characteristics, can be cast up to 4” thick, and can be machined to create unique shapes and configurations. Where extruded acrylic is limited to the die used to shape the materials in mass quantities, cast acrylic is often mixed in small batches by combining a liquid monomer and powdered acrylic polymer and then pouring it into a mold. The hardened material is then exposed to heat and pressure to clarify the acrylic prior to machining it to shape.

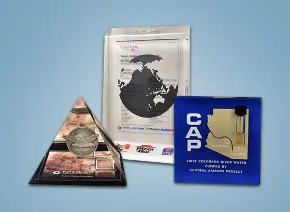

You will often find cast acrylic used in the following types of acrylic awards:

- Acrylic Embedments

- Acrylic Trophies

- Acrylic Plaques

- Acrylic Medals

- Specialty Awards

- Corporate Deal Toys

- Financial Tombstones

Now let's take a look at what is involved with engraving acrylic.

We discussed earlier in the article the differences between cast and extruded acrylic substrates and for the remainder of this post we will only be referring to cast acrylic.

Acrylic Engraving Methods

There are primarily three different ways to engrave cast acrylic – hand engraving, rotary engraving, and laser engraving. We will touch lightly on the hand and rotary methods, and focus primarily on laser engraving since it is the most common engraving method today on acrylic substrates.

Hand engraving or intaglio

Hand engraving or intaglio

Hand engraving, or to use the technical term intaglio, is a process of using a small hand held powered rotary device similar to a dental drill or dremel to carve deep into the acrylic block or add designs and text by hand. This was first introduced to the awards industry in the early 80’s by Wald Designs, an acrylic manufacturing company.

Notice the depth of engraving where by the artist used a fine tipped rotary tool to add internal details to the hummingbird and cactus. This art form is popular among collectors and has a very unique look that when combined with color often create amazing works of art.

CNC Rotary Engraving

CNC Rotary Engraving

The best way to describe rotary engraving into acrylic would be to imagine a very precise router similar to that which you would use to add and etch to a piece of wood or to route letters into a sign.

Rotary engraving is done with the assistance of a CNC (computer numerically controlled) engraver driven by a desktop computer. There are many different manufacturers in the industry, but one of the most common in the awards and recognition industry is Vision Engraving & Routing Systems.

Engraving depth and letter thickness is controlled by configuring the CNC width cutters and the depth by settings within the software. Attached to a spinning motor, a spindle carries the cutter which drops into the acrylic while spinning. The effect is a frosted white channel cut into the acrylic suitable for color filling, back lighting, or simply left as is to appreciate the contrast between the clear acrylic and the frosted letters.

.

Laser Engraving Acrylic

Laser Engraving Acrylic

Laser engraving technology was introduced to the awards and recognition industry in the early 80’s. Early machines were big bulky units that relied on scanning a document which then translated the graphics and text to the substrate. Since the late 80’s and early 90’s personal desktop laser engravers have become more common.

Often driven by vector based graphics programs like Corel Draw, laser engravers have the ability to engrave multiple substrates with the most common being cast acrylic. By focusing a laser at a specific distance from the acrylic substrate, lasers are capable of gracefully marking acrylic with a very defined frosted white impression.

Laser engravers are very fast and are typically configured with CO2 laser tubes available in 30, 40, 50, or 60 watt options. Though all of the wattage options produce similar results, the higher the power the faster the laser can run to engrave the acrylic with graphics or text. US Acrylic Awards is partial to Trotec Laser engraving equipment for their speed, accuracy and high quality acrylic engraving capabilities.

Our final comments on acrylic engraving material options

Modern acrylic engraving is used daily in the manufacture of awards, embedments, plaques, and medals at US Acrylic Awards. In conjunction with our LaserCut™ technology – laser engraving is often applied to our products to personalize them with a recipient's name and what the award was presented for.

Our design team is always looking for unique opportunities to create custom acrylic awards. Give us a call to find out how we can personalize an awards program to suit your needs.

Written by noptim… unleash the power