Since 1984 — Greg and Scott Smith have been manufacturing acrylic awards.

Since 1984 — Greg and Scott Smith have been manufacturing acrylic awards.

Happening upon a newspaper ad for a small acrylic embedment company for sale — Greg and Scott decided to investigate further. This was the beginning of an amazing journey that would take a business doing less than $600 a month in gross revenues to the powerhouse of corporate recognition it is today.

The facts on US Acrylic Awards

The facts on US Acrylic Awards

After meeting with the owners, both Greg and Scott grew excited about the acrylic embedment process and its potential. Casting objects into crystal clear acrylic resins from coins and police badges to miniature prospectus books and patents had immense appeal and promise.

The Acrylic Embedment Learning Curve

The Acrylic Embedment Learning Curve

Like many small business adventures, the first three years were lean. Building a business essentially from scratch with no recurring customer base, no valuable knowledge of the industry, and little familiarity of how to manufacture an embedment required drive and determination. Both took a hands-on approach to developing repeatable manufacturing processes that would make Clear Image, Inc. the parent company of US Acrylic Awards — one of today’s most respected acrylic award manufacturing companies in the US.

Then and Now

Then and Now

— The Acrylic Manufacturing Process

The early days of setting up shop with a small autoclave, a wet belt sander, a craftsman table saw, and few aluminum molds — the fun began. Always innovators, the Acrylic Masters as we call them knew the importance of improving facilities, equipment, and developing a staff of highly cross trained employees who care as much about the products produced as themselves.

Manufacturing Acrylic Awards Today

Manufacturing Acrylic Awards Today

Now with a 10,000 square foot facility dedicated to manufacturing all kinds of acrylic products, there is not a day that goes by without something truly unique coming off the production line. Walking through the building you will see three edge finish machines, six autoclaves, four table saws, a panel saw, a lathe, six acrylic buffing wheels, two large flatbed UV acrylic printers, a complete screen printing facility, two Trotec Laser Engravers, a 400 watt laser cutter, a 320 watt laser cutter, a 150 watt laser cutter, an automatic bagger, automatic acrylic benders, hydraulic cutters, multiple drill presses, table routers, and a skilled crew with expert knowledge of each piece of equipment.

The Crew at US Acrylic Awards

The Crew at US Acrylic Awards

With a staff of 12 employees, Greg would say his favorite thing about owning US Acrylic Awards is trying to stay innovative and making people happy. You can see that attitude exemplified by both brothers as they manage their people and interact with clients.

Innovation

— The Future of Acrylic Recognition

Looking to expand their reach and offer high quality acrylic awards to more clients throughout the US and Canada — Greg and Scott decided to create the most innovative eCommerce site in the recognition industry. With the ability to shop from desktop or mobile — you can now create custom acrylic awards and deal toys, and know the cost on the fly. Plus US Acrylic Awards is available by phone or chat if you have questions about our products.

Selling Acrylic Awards Online

With endless customizable options and multiple price attributes associated in the product line — they were faced with the challenge of creating a site accessible via desktop and mobile platforms allowing visitors to choose options and calculate accurate prices. Making that happen was no easy task, yet both Greg and Scott would say it was worth the challenge.

As you shop acrylic awards on USAcrylicAwards.com — the ease with which you can calculate the exact price will astound you. Plus, each of your selections will be transferred to your order details to speed up and improve the manufacturing process while reducing the risk of errors — always a priority at US Acrylic Awards.

Acrylic Award Manufacturing

If you’re ever in Glendale, Arizona and you’re interested in taking a tour — give us a shout. You can expect to see a well-designed facility with quality American Manufacturing standards taking precedence at every stage of production.

Manufacturing at the cutting edge of technology with two high speed laser engravers, three high power laser cutters and two large flatbed UV printers — the creativity and quality standards are second to none. And watching the expert artists and acrylic finishers polish each award to perfection is an impressive sight.

Interesting answers to questions of the Acrylic Masters

Interesting answers to questions of the Acrylic Masters

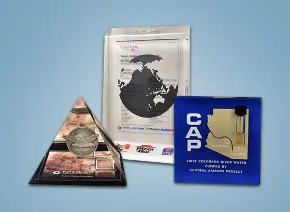

With over 30 years of experience in the awards industry — we thought it might be fun to ask some direct questions of Greg and Scott to get their perspective on a few subjects. Don't hesitate to comment on this post and ask other questions of US Acrylic Awards. We're always open to inquiries about our products and services. By the way — the image to the left is an example of our creative LaserCut™ Acrylic Award capabilities.

Do you manufacture other acrylic products?

- Anything made out of acrylic – including furniture, picture frames, signage, face shields, and decorated promotional products.

What's your all-time favorite award manufactured?

- Our first large order was casting 500 lucite embedments with a 3-dimensional Statue of Liberty cast inside. It was presented by Coca-Cola America for the commemoration of their renovations completed in 1986.

- Image of Statue of Liberty cast in clear lucite shown above.

How's US Acrylic Awards different?

- Every product in our line is 100% Manufactured in the USA! Designed by acrylic artisans who know the properties of acrylic with the most advanced equipment in the industry. Backed by a 100% Quality Guarantee that is second to none in the awards field.

- Quality products created by quality people who care about corporate recognition and crafting the most unique acrylic awards available.

US Acrylic Awards is ready to make your award projects come to life. We hope you enjoy shopping our selection of awards and look forward to partnering with you to motivate and encourage your staff.

Written by noptim …unleash the power