11-30-2021

Investors Snap Up Metaverse Real Estate in Virtual Land Boom

10-25-2021

E-sports joins the SPAC craze as FaZe Clan seeks to go public

9-20-2021

Royal Dutch Shell Sells Permian Basin Oil Holding for $9.5 Billion

8-26-2021

Forbes plans to go public in a $630 million SPAC deal.

7-19-2021

Historic Cherry Lane Theater Sold for $11 Million

Recent corporate deals reported by the New York Times

From mergers and acquisitions to real estate… Big Deals are not only profitable for many involved, but an opportunity to recognize both the big and little players involved.

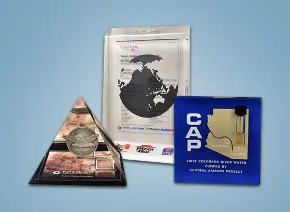

From the initial idea to the closing bell, it’s important to recognize the people that made it happen. And when you want to say thank you with a gift that represents the momentous event, Deal Toys set the stage to remember the time and effort it took to bring it all together.

What’s a Deal Toy you ask? You can learn more by reading our article ‘What is a Deal Toy’ that dives deep into the history, materials, and production times required to create custom deal toys.

Since Deal Toys are one-of-a-kind souvenirs to commemorate an event, let’s take a look at some questions that are often asked by new clients during the design process.

How creative can I get with the design?

How creative can I get with the design?

The creative process is more often than not dictated by budgets and time constraints. With malleable materials like acrylic, metal, and wood – custom shapes and colorful designs are the wave of the future.

How fast can you complete my order?

How fast can you complete my order?

Always important to the design process, the speed at which production happens has a lot to do with design and manufacturing requirements. A simple Lucite® Embedment with a vaccine vial and no personalization can be done much quicker than a combination of custom acrylic and metal shapes with color printing and moving parts.

Our recommendation is to order early, get creative, and have some fun with the design process.

How many do I need to order?

How many do I need to order?

Though we’ll do as few as one deal toy at a time, the cost to design, manufacture and ship small runs often limits the design process as many companies either have a limited budget or a set price in mind. Our average deal toy order is about 40-50 pieces since the 2008 banking crisis, but we are seeing those numbers increase recently.

Designing Excellence

It’s important to note that not all Deal Toys are created equal, and for that matter neither are all deals. It goes without saying that a multibillion-dollar deal is likely to have different requirements than a multimillion-dollar project.

Though the process is similar no matter what goes into design and manufacture, the fact is that it still requires exceptional client/manufacturer communication and a commitment to excellence not often found in today’s world. Let’s review the most common steps required to create a custom Deal Toy that will be a treasured memento for years.

Initial Communication

Initial Communication

We call this first touch – because this is the first opportunity we have to present our capabilities. Whether via online order, chat request, contact page, or personal phone call, initial communication is where creativity begins.

Normally, basic information from verbal descriptions, an emailed sketch, or a photo of something a client has seen are discussed and shared. An understanding of budgets, quantities, and delivery times must be considered as the customer service rep reviews and discusses potential design options.

Conceptual Sketches

Conceptual Sketches

Exploring initial ideas for Deal Toy Design often happens over the phone, via email, or through client conceptual drawings. A simple freehand sketch of the shape, embedded location of the cast item, projected text, and color combinations are helpful, but if you’re new to the process we can help you brainstorm to design the right product to recognize your team.

Preliminary Graphics

Preliminary Graphics

The magic happens in the art room! From concept to visual renderings that often include 2D representations of front and side views. Understanding the placement of cast objects, logos, text, and acrylic components are helpful to make sure both the designer and the client are on the same page.

It’s often at this stage that customers begin to see their Deal Toy vision come together.

Dialing in the Design

Dialing in the Design

Getting it right the first time means making sure the final product is symmetric with proper placement and margins. It’s at this point we would require any customer supplied cast objects, text, and logos with corporate graphic standards to make sure we combine it all together in order to create a unique piece of art.

We require final designs to be approved and signed off on by our customers in order to send them back to our production team.

Prototype Sample

Prototype Sample

On larger orders, if time permits – we often recommend a pre-production sample. The pre-production sample is a full scale sample of the final product that is often sent for final approval prior to manufacturing.

This is a perfect time to share the sample with any of the important decision makers as we can still make minor tweaks at this stage without significant cost.

Modifications

Modifications

Minor modifications can be made to the design and an additional sample if needed, but often our customers rely on another final drawing to help visualize the final product. Once the Deal Toy Design is fully approved, our service team establishes a timeline with manufacturing.

Production Schedule

Production Schedule

Fine acrylic award manufacturing is different in a lot of ways than other recognition products. Though acrylic is crystal clear – the process to make it that way takes skill and patience.

Each step in the production schedule from creating the molds to final polishing and packaging for shipment, must be accounted for in order to be certain your product is pristine. Here is an interesting video showing the manufacturing process to create Custom Shaped Laser Cut trophies.

Notice the attention to detail and care taken to create the graphics, print the logo, laser cut the acrylic sheets, square off the bottoms, polish, glue, and prepare for shipping on each award manufactured.

Careful Shipping

Careful Shipping

Though acrylic is inherently durable, the process of shipping is just as important as design and production. To spend the time required to make acrylic deal toys just right and then package them poorly would be a shame.

It’s at this stage that our shipping team inspects each award carefully for flaws that may have made it past our production crew. Defects are sent back for correction and or recreated to ensure your deal toy awards are the best they can be.

Final polishing, bagging, and individual boxing happens prior to bulk packing with plenty of protection to keep your deal toys safe.

About US Acrylic Awards

We’re here to help you design the most unique Deal Toy within your budgetary constraints. Our customer service team is always looking for a challenge and our design team is the best in the industry. All of our awards are manufactured right here in the USA for quality control and quick ship if needed.

Keep us in mind the next time you land a big deal – we make playing with toys fun in the office!

Written by noptim… unleash the power