Lasers are changing the way recognition is done in the workplace.

Never in the history of corporate recognition programs has there been such an upturn in the use of LASER equipment to produce fine awards. With a unique ability to cut custom shapes and mark acrylic – lasers have created an era of exiting trophy options. From contoured shapes to beautiful laser engravings – LASER technology can transform the way your employees experience appreciation in the workplace.

The growth of laser usage in the recognition awards industry.

The growth of laser usage in the recognition awards industry.

Lasers (Light Amplified by Stimulated Emission of Radiation—LASER) revolutionized the trophy and awards industry starting in the late 1980’s when the cost of small laser engravers came down to a level that made sense for many trophy shops around the world. Advancements in technology have taken what used to be a simple marking tool that competed with traditional engraving methods to a powerful option for creating unique shapes out of acrylic sheet stock contourable to just about any corporate logo or event image. Now with the availability of lasers that can easily cut up to 1” thick acrylic with fine polished edges – the traditional trophy is beginning to be a quickly fading long-lost memory.

Marking with laser engravers.

Marking with laser engravers.

Laser engraving is now the most popular decorating process in the awards industry. Driven by powerful software like Corel Draw or Adobe Illustrator, accomplishing fine detailed engraving results are the norm. A common laser engraving manufacturer, Trotec, now has laser engravers that will raster engrave up to 170 inches per second with exacting detail and accuracy. Capable of engraving anything from acrylic awards, glass, crystal, plastics, and markable metals, to name just a few – it is unlikely that any award made today is not marked with a laser marking device.

Cutting with lasers.

Cutting with lasers.

Laser engraving and laser cutting are two completely different processes. Laser engraving uses a process called raster engraving whereby the laser gracefully fires in exacting locations as it moves across and down the laser field. Laser cutting on the other hand – follows a detailed vectored image with power and speed settings configured to optimize the final piece by making sure the edges and surfaces are flaw free. Laser cutting is now common in acrylic award manufacturing where a few suppliers in the industry have the ability to cut thick acrylic sheets into custom shapes that contour logos.

Watch this video showing our Kern laser cutter cutting through 3/8” thick acrylic.

Lasers have made a huge impact in the production of acrylics and manufacturing processes. As technologies improved over the years so too has the ability to create fine custom corporate recognition awards. We’re proud to walk you through one of our unique products that takes advantage of multiple laser technologies below.

Making custom shaped acrylic trophies at US Acrylic Awards.

Because lasers are so accurate, creating custom shapes is an artform that requires skilled artists to take a corporate brand or event image and contour it to draw attention to its design. It all begins with your image, a conversation about your vision, and an artist with the skills to contour a shape into a unique design. US Acrylic Awards offers five thicknesses of custom shapes and seven size options of each – so finding the right one for your event will never be an issue. Our economy line is 1/4” thick, value line is 3/8” thick, our choice line is 1/2” thick, our premier line is 3/4” thick, and our elite line is 1” thick clear Lucite®. Each is able to be cut with one of our three laser cutting machines. Often in our custom LaserCut line we do full color ultraviolet printing to enhance the finished look of the trophy. The color is printed on the back side of the acrylic with an opaque white background to make the color pop against the clear materials. Laser engraving is often used to personalize the awards after they’re printed and cut to add names and any other information pertaining to the recipient.

Let’s walk through the steps it takes to create a LaserCut Acrylic Award

Customer service

From the moment your order comes in, one of our customer service reps will be attentive to the details. You can expect a phone call to go over the order, discuss options, and make sure the final product will be done to your liking. Once comfortable with the details it will be sent to design where an artist will custom contour the shape and send a proof for final approval prior to creating the cut and print files.

On to production

Once approvals are made and the production files created, your project will be printed on a Mimaki flat bed ultraviolet printer. The color accuracy of the Mimaki is second to none and you can see in this image how the color is printed down in reverse with a white background.

Once the printing is completed, the printed sheets will be taken to one of the laser cutters to cut the custom shape. Depending on the thickness of the material, different laser settings will be applied to ensure no burning happens on the edges or surfaces of the awards. The base of the cut piece will then be run through our diamond honing machine to give it a perfect edge for gluing if required or to make sure it stands upright freely.

Laser engraving

At this stage, if required, a laser engraving machine may be used to personalize the trophies. Adding names and pertinent information to the recipient is often done at this stage prior to final finishing. Laser engraving marks acrylic with a light frosting by removing the surface layer.

Finishing and shipping

Quality control is a very important step – and one taken very seriously by our crew. Careful gluing to the base if required, as well as polishing and inspecting for flaws or scratches that may have happened in production is our final opportunity to make sure the trophies are done right.

Each is packaged in a clear poly bag and individually boxed for added protection in shipping.

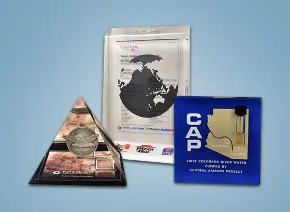

Here are a few examples from our LaserCut line

Written by noptim… unleash the power