At US Acrylic Awards, every creation tells a story of craftsmanship, innovation, and meaningful recognition. Our Spotlight Series highlights each of our signature acrylic collections, focusing on the design, materials, and production methods that make them unique.

Each Acrylic Award in this series is Made in the USA, crafted with precision, and can be personalized with Laser Engraving or Full Color Printing . These designs help turn recognition for leadership, innovation, or achievement into lasting works of art.

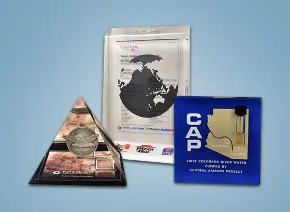

Today, we are highlighting one of our most treasured collections: Composites™ Acrylic Awards.

Layered Design Created Through Cast Acrylic Craftsmanship

The Composites™ Acrylic Award line stands out not only for its look, but also for how each piece is made. Like the cast acrylic embedments in our Array™ line , Composites™ trophies are created through a true casting process, not made from fabricated flat acrylic sheets.

Each Acrylic Trophy starts with a mold made to create its custom shape. These molds use aluminum, cardboard, or both, depending on the design. Strips of Staron® material are cut and prepared to be cast into liquid acrylic resin, forming the layered elements that define this collection.

This process makes the layered materials a true part of the award, not just surface accents. The result is depth, clarity, and lasting quality that enhances every Acrylic Award in the collection.

Distinctive Shapes with Dimensional Presence

The Composites™ Acrylic Awards collection offers a range of shapes that show off the layered construction and architectural depth:

- Composites™ Rectangle Acrylic Awards : Clean, modern lines highlight the embedded materials and provide plenty of space for Laser Engraving or Full Color Printing.

- Composites™ Square Acrylic Awards : Balanced and modern, emphasizing symmetry and material contrast, ideal for corporate and executive recognition.

- Composites™ Circle Acrylic Awards : A timeless circular profile that represents unity and teamwork, with the layered accent adding a refined, modern touch.

- Composites™ Hexagon Acrylic Awards : Six-sided geometry adds visual interest and dimension—excellent for innovation, engineering, or problem-solving achievements.

- Composites™ Obelisk Acrylic Awards : Tall and sculptural, the obelisk shape conveys strength and stability through its vertical form.

- Composites™ Octagon Acrylic Awards : Eight crisp edges catch the light beautifully, creating a premium presentation that reflects excellence from every angle.

- Composites™ Peak Acrylic Awards : Angled lines and a tall shape represent growth, performance, and progress.

- Composites™ Apex Acrylic Awards : With a sharp, upward-pointing silhouette, the Apex design is perfect for top-tier recognition and President’s Club–style honors.

Each shape is available in multiple sizes, allowing organizations to maintain a consistent design language across recognition levels while tailoring scale to each achievement.

Precision Customization with Lasting Impact

Customization is a key feature of the Composites™ line. After casting and finishing, each Acrylic Award can be personalized with Laser Engraved text for a frosted look or with Full Color Printing for bold branding and detailed artwork.

The layered design separates text, graphics, and embedded materials, creating a multi-dimensional look that stands out. Logos are sharp, colors stay bright, and personalization feels thoughtfully placed, not added at the last minute.

This makes Composites™ a great choice for organizations looking for a high-quality Acrylic Trophy that offers both design depth and clear corporate branding.

Cast, Cured, and Finished by Skilled Craftsmen

After the mold is ready, a small amount of liquid acrylic resin is poured in and left to partially cure. Then, the prepared Staron® strips are placed in the mold, and more acrylic is added to reach the correct thickness.

The molds are left to cure, then placed in an autoclave where pressure and heat are applied for 8 to 10 hours. This step removes air bubbles, makes the acrylic clear, and strengthens it. The acrylic also shrinks by about 25%, so it comes out of the mold easily.

From this rough cast, skilled craftsmen use saws, sanders, planers, and polishers to shape and finish the piece. This process turns raw cast acrylic into a finished Composites™ Acrylic Award.

Why Choose Composites™ for Your Recognition Program

Composites™ Acrylic Awards are perfect for organizations that value craftsmanship, quality materials, and thoughtful design. Each Acrylic Trophy stands out visually and shows intention, quality, and lasting value.

Whether you choose Laser Engraving for a subtle look or Full Color Printing for bold branding, Composites™ awards are built with a level of quality and detail that makes them a treasure when received.

When recognition calls for more than a traditional award, the Composites™ line offers depth — both visually and symbolically.

Explore the Composites™ Collection

Explore the full Composites™ Acrylic Awards collection to discover available shapes, sizes, and customization options. Experience how cast acrylic craftsmanship and layered materials come together to create recognition pieces that are as meaningful as the achievements they represent.

Because true recognition is built — not just assembled.