Color on acrylic, especially clear acrylic works wonderfully in the creation of fine acrylic trophies and deal toys.

If manufactured properly, Lucite® – the purest form of acrylic, is by nature crystal clear and an exceptional substrate for adding color. Understanding the nature of Lucite® and color theory will help you to make the best decisions when selecting acrylic trophies, plaques, or medals.

In this article we are going to explain the process of manufacturing high quality acrylics, how color is used in manufacturing awards, and provide six valuable tips for adding color to your recognition programs.

What is acrylic?

This is a question we’re asked a lot – and it’s one that is best answered by a simple explanation of how the solid state of clear Lucite® or acrylic is fabricated.

Let’s begin by describing the two main components that are required to complete the chemical reaction that ultimately forms the acrylic.

Poly(methyl Methacrylate) PMMA – also known as acrylic, acrylic glass and many other trade names such as Lucite®, Acrylite® and Plexiglas® is a synthetic resin created by the polymerization of methyl methacrylate.

The primary component in polymerized acrylic PMMA, is Methyl Methacrylate (MMA), a colorless liquid that when combined with a polymer powder as a catalyst begins a chemical reaction requiring consistent atmospheric percentages of nitrogen, heat, and pressure to complete the reaction.

It’s worth noting that other less costly forms of PMMA can be and often are manufactured without the use of heat and pressure. However in this case – the best acrylics for manufacturing exceptional quality acrylic awards and deal toys are required for both bubble free clarity and laser engravability.

How is color used in award manufacturing?

There is no doubt that color can influence our mood, thinking, and decision making. We would argue that color in the design of trophies and awards is not just important, but a fundamental aspect to how the prize is received.

Dictionary.com defines color as *the quality of an object or substance with respect to light reflected by the object, usually determined visually by measurement of hue, saturation, and brightness of the reflected light; saturation or chroma; hue.

We could spend a lot of time explaining the meaning of color, but in this article, we want to focus on the way color may define, accent, and highlight a corporate brand.

Color accents are primarily added to acrylic substrates by direct ultraviolet printing, casting within the acrylic mold, adding color components, and color filling after laser engraving to a depth that allows for paints to fill the void.

Direct Ultraviolet Printing

Direct Ultraviolet Printing

Is the newer more advanced way of adding color to acrylic. Though silk screen printing is still used in some cases like adding metallic colors – ease, accuracy, and color management of direct printing cannot be matched by manual methods.

You can read more about UV Printing on Acrylics in this article.

Casting Colors Into Acrylic

Casting Colors Into Acrylic

Is another popular method of adding color. Offering a sleek polished look – colored strips of Lucite® are cast deep inside the liquid acrylic mold prior to applying heat and pressure to literally embed the color seamlessly into the crystal clear shape.

Colored Acrylic Components

Colored Acrylic Components

Can be fabricated into acrylic trophies and are often the equivalent of custom cut and polished pieces of acrylic that are designed into the overall concept of the award. In some cases color is simply added by meticulously gluing a base, but more often than not custom shapes can be achieved by fabricating the acrylic to create a deal toy award with depth and uniqueness.

Color Filling Acrylic

Color Filling Acrylic

And finally, rarely is there a day that we don’t Color Fill a laser engraved name or logo on a trophy or embedment. By setting a high powered laser engraver to engrave the acrylic at a depth that will allow for adding paint or metallic waxes to the void, adding a line of color in a body of text can highlight one aspect of the appreciation wording.

For those of you that are interested in more information on color – check out our article on Using Color to Optimize Award Design that goes deeper into the idea of color psychology in the design process.

Now that you understand where acrylic comes from and the most common ways color is added to awards, let’s go over our six tips for adding color to your recognition program

Number one: Enlist our design team

Number one: Enlist our design team

As experts in graphic design and understanding the characteristics of acrylic substrates – our team is experienced in creating the finest acrylic trophies throughout the US and Canada. From rough sketch to completion, our award winning design team is committed to making you look good.

Number two: Don’t be afraid to experiment with color

Number two: Don’t be afraid to experiment with color

It can take practice to become confident with color, but if you have a concept for an award or deal toy that you think may look good, ask for a pre-production proof. Creating a virtual proof is a safe way to experiment with color and will provide a way for you to get a sense of the color to acrylic ratios prior to manufacturing.

Number three: Trust your brand identity

Number three: Trust your brand identity

It’s important to understand that your corporate brand identity was likely created by professionals that know and understand color and how it should be used. If you are part of a large corporation, there are even graphic standards that spell out exactly how you may use the logo that may also include fonts and background color options.

Number four: Keep it simple

Number four: Keep it simple

Though there may be specific reasons to get crazy with color, in most cases simple is better. Pick one or two complementary colors. Complimentary colors are opposite hues on a color wheel. Yellow and purple, orange and blue, red and green are the most basic examples of complementary colors.

Try picking a color directly opposite your primary logo color as a complementary color; it is likely to make your logo and the complementary color pop by simultaneously contrasting each other.

Number five: Look at samples for inspiration

Number five: Look at samples for inspiration

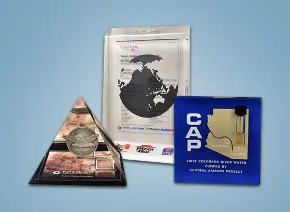

There is no better way to understand how color can and should be used on acrylic awards than to look at ideas and see what you like. Whether you find something you like online or browse our Custom Gallery Pages – nothing bad can happen from learning from the success of others.

Number six: Look to how colors make you feel

Number six: Look to how colors make you feel

It’s important to be mindful of your tolerance for color. If you try a color combination and don’t like the way the proof turned out – by all means try something different. Our team can help and will often offer advice early in the process to help you succeed with your award color management challenges.

Stepping back in time, even just ten years ago – color was not often on the radar of most of our customers looking to create recognition trophies.

Now, with so many unique ways to add color to acrylic – we can’t really tell you if there is actually a right and wrong way to use it in design. Except to say look around you – at the grass, the flowers, the trees and the sky; color was in the beginning and will always be with us.

Be creative. Have fun. Keep it simple.

We hope you enjoyed this article as much as we enjoyed writing it. US Acrylic Awards is an American manufacturer of fine acrylic deal toys, trophies, and awards. Each of our custom and stock awards have been created by craftsmen in Glendale, Arizona for nearly 40 years.

Written by noptim… unleash the power