When casting Lucite® polymers and monomers, optical clarity stands out as the defining feature required of high quality acrylic embedments.

It’s this optical clarity that our team takes very seriously. Optical clarity as it relates to acrylic embedments essentially refers to the distortion that may happen when you look through the clear acrylic material at the embedded item.

With nearly 40 years of experience casting acrylic in the US, our team has a pretty good idea of the items that will and won’t cast well. This article will take a closer look at the materials that react negatively to the heat and pressure generated during the acrylic polymerization process.

First off, let’s discuss what a Lucite® or acrylic embedment is and how they can be used to celebrate achievement, recognize excellence and honor a job well done.

What is an acrylic embedment?

An acrylic embedment is a solid piece of clear Lucite® made by mixing two chemical compounds. Combining a crystal clear liquid monomer and a flour-like powdered polymer into a substance that looks similar to a very thin cake batter that will ultimately be transformed into crystal clear Lucite®. Depending on the item to be embedded, the liquid monomer and polymer combination will be mixed somewhere between a 70/30 and 30/70 ratio.

The mixture is poured into oversize molds utilizing a layering process allowing for final fabrication that often includes cutting, sanding, and polishing. By layering the mixture in the molds, items to be cast can be gracefully suspended inside the raw acrylic compounds prior to polymerization. Allowed to sit for several hours, the cast material will set up with a cloudy appearance that will be clarified during the polymerization process by applying pressurized nitrogen at approximately 140 psi and controlled heat when placed inside an autoclave for 8-10 hours.

While in the autoclave, a process called polymerization takes place creating a chemical reaction that ultimately generates crystalline chains of molecules. It’s this polymerization process that transforms the milky white substance into a crystal-clear Lucite® block that can be fabricated into specific shapes with traditional shop tools and polished to enhance the item embedded inside.

How are embedments used?

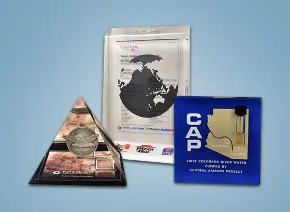

An acrylic embedment is a versatile product that is often used as an award to recognize a corporate team by casting a sample of the product or item they produced. However to quote Dr. Seuss, “It has other uses. Yes, far beyond that.”

Though a majority of the Lucite® embedments we create are used to recognize excellence, they are also often used for sales tools, deal toys, financial tombstones, FDA vaccine approvals, retirement gifts, and donor incentives.

Let’s get back to the main reason for this article, the optical clarity of acrylic embedments and the items that do and don’t cast well.

As we mentioned above optical clarity is always our first priority, and one of the main factors when it comes to embedding items into acrylic. US Acrylic Awards has been casting acrylic for nearly 40 years now and has experienced great success, but it’s in our failures that we have learned, progressed, and developed techniques to cast items with the optical clarity you should expect.

Here are a few examples of items that have not embedded well inside Lucite®

Heat, pressure and solvency are the main culprits we've found to affect optical clarity in the acrylic embedding process.

Since the primary goal with every embedment we produce is to ensure optical clarity, let’s take a look at some of the materials we have found to distort the natural composition of clear acrylic.

Remember we discussed the process of casting acrylic materials which requires subjecting the set-up mixture to pressure and heat while inside an autoclave. We also discussed the mixing ratios (or solvency) which often plays a significant role in the final outcome.

It’s these factors that can affect many materials that you may wish to have embedded inside an acrylic block. Plastics, rubber, organic materials, painted items and many metal items are subject to casting failure.

Plastics

Plastics

Due to the heat generated during the chemical reaction (approximately 300 degrees fahrenheit), injection molded plastics like Bic® pens, Tupperware®, key fobs, and model parts can warp or bubble inside acrylic.

Rubber

Rubber

Heat and chemicals break down rubber causing them to bleed off into the surrounding Lucite® material. Items like chunks of tire, the rubber on matchbox car tires, balls, and industrial rubber components tend to bleed into the clear Lucite® creating a cloudy appearance.

Organic materials

Organic materials

Items that are organic in nature such as fresh flowers, leaves and yeast products like bread often cloud or discolor the clear Lucite® during the casting process. Flowers are particularly susceptible to turning brown inside acrylic castings.

Painted items

Painted items

The heat and pressure of polymerization often causes acrylic and oil painted items to peel, wrinkle, or bleed. Very often pins, challenge coins and medallions that are decorated with soft enamel will bleed into the surrounding acrylic.

Polished metals

Polished metals

Though metal often casts well, when highly polished it can cause cavitation. Cavitation is where the acrylic does not adhere to the item causing a silvery looking finish. Another issue that should be considered is that extremely cold weather may split or crack the Lucite® when the acrylic shrinks and the item inside is stable.

Tech Devices

Tech Devices

Such as cell phones, even with the battery removed are not great candidates for embedding. Tiny cracks and crevasses on the devices allow small air pockets that when exposed to the pressure and heat of polymerization are pulled to the surface and are often very visible flaws in the final piece that cannot be corrected with traditional fabrication techniques.

If you've made it this far into the article – likely you’re asking yourself if your item can be cast inside acrylic.

Though we make every attempt to create exceptional embedments, some items just do not cast well. It’s our policy to run a factory test on large orders to ensure the embeddability of the item to be cast.

Our customer service team is always willing to share our knowledge with you and will help determine the likelihood of a successful casting of your item. We're always up for a challenge and look forward to creating works of art to highlight your corporate or personal successes.

What if my item can’t be embedded in acrylic?

If we determine that your item is not a candidate for the embedment process, as a manufacturer of acrylic awards – we can often create a solution to display your items and protect them for a lifetime of viewing enjoyment.

For instance, our Allure™ Acrylic Encasement line features the laser cut accuracy of contouring your item, cutting a cavity out of the inner acrylic sheet, and then sandwiching it between a clear acrylic cover and your choice of a colored or clear acrylic background.

Give us a call, we’re here to help!

We want to be your embedment partner, so let’s talk about your project. Our US factory located in Glendale, Arizona is staffed with the finest acrylic craftsmen and women in the industry. We treat every project as if it were our own and our customer service is second to none.

When we're in doubt, we're always happy to run a test of your item... Sometimes we too are surprised.

This French fry was cast in acrylic over a year ago!